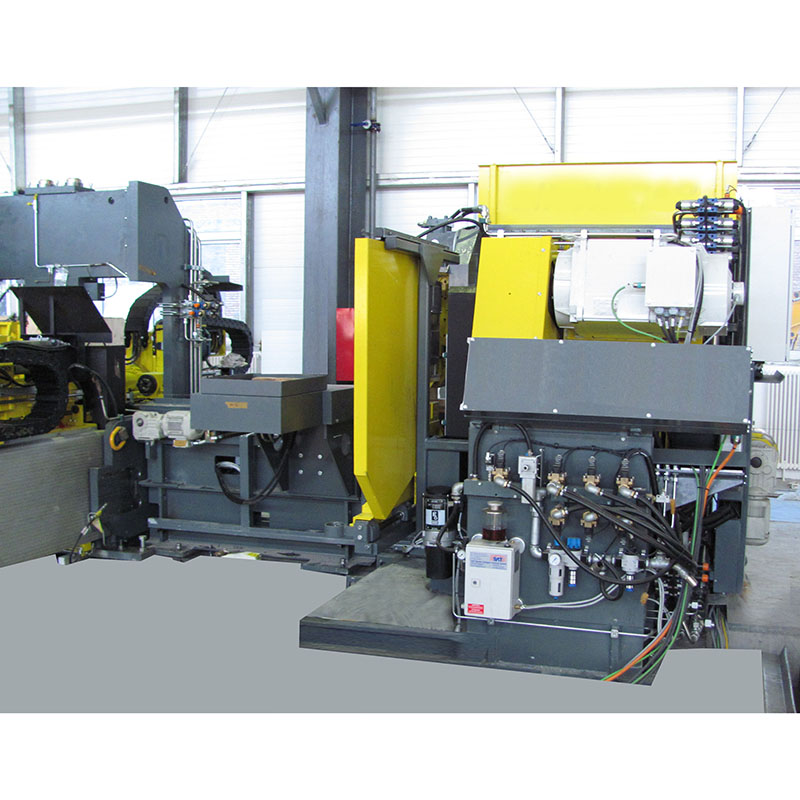

RDS13 CNC Rail Saw uye Drill Combined Production Line

| Item | parameter | Tsanangudzo |

| Basic njanji modhi | Rudzi rwezvinhu | 50Kg/m.60kg/m,75 Kg/m kuoma 340~400HB |

| Alloy simbi musimboti njanji, alloy simbi kupinza, kuoma 38 HRC~45 HRC | ||

| Rail size | Hurefu hwezvinhu | 2000~1250mm |

| Kugadzirisa zvinodiwa | Materialurefu | 1300~800mm |

| Materialkureba kushivirira | ±1mm | |

| Kugumisa chiso perpendicularity | <0.5mm | |

| Drilling dhayamita | φ31~φ60mm | |

| Gomba dhayamitakushivirira | 0~0.5mm | |

| Gomba kureba kureba | 60~100mm | |

| Main technical parameters yemuchina | Sawing nzira | Circular saw (high speed) |

| Spindle mota simba | 37kW | |

| Saw blade diameter | Φ660mm | |

| Kumhanya kwakanyanya kweX axis | 25m/min | |

| Kumhanya kukuru kweZ axis | 6m/min | |

| Kuboora spindle mhando | BT50 | |

| KucheraSpindle speed | 3000r/min | |

| KucheraSpindle servo mota simba | 37kW | |

| Kumhanya kukuru kwe X, Y, Z axis | 12m/min | |

| Chamfering spindle type | NT40 | |

| Chamfering spindle RPM Max. | 1000 | |

| Chamfering spindle mota simba | 2.2 kW | |

| Movement kumhanya kweY2 axis uye Z2 axis | 10m/min | |

| Magetsi anogara magineti chuck | 250×200×140mm(mumwe200×200×140mm) | |

| Kusveta basa | ≥250N/cm² | |

| Chip kubvisa system | 2set | |

| Chip conveyor mhando | Flat cheni | |

| Chip kubvisa kasi | 2m/min | |

| CNC system | Siemens828D | |

| Nhamba ye CNC masisitimu | 2set | |

| Nhamba ye CNC axes | 6+1 akisi,2+1 akisi | |

| Height of worktable | 700mm | |

| Height of worktable | anenge 37.8m×8m×3.4m |

1. Pane saha blade chip yekubvisa mudziyo pane sawing unit, iyo ine basa rekubvisa sawdust kubva pasaha blade.Iyo inotonhorera uye yekuzora mudziyo inozora uye inotonhodza nzvimbo yekucheka, iyo inovandudza hupenyu hwesevhisi yesaw blade.guide rails, uye iyo mobile column inoiswa pamubhedha wemashini.

2. Coding system

Iyo coding system yakaiswa parutivi rwekunze kwesimba remusoro wegondohwe, uye yakashongedzerwa nekombuta inotambira kuronga uye kutonga iyo coding system.

3. Drilling unit

Iyo mbiru chimiro inogamuchirwa, uye mbiru inotora simbi ndiro yakashongedzwa chimiro.Mushure mekuita annealing uye yekugadzira kuchembera kurapwa, kugadzikana kweiyo kurongeka kwechokwadi kunovimbiswa.

4. Kuchera musoro

The drilling headstock imhando yegondohwe chimiro chine kusimba kwakasimba.Bhandi renguva rine simba rakanyanya kusimba, hupenyu hurefu, ruzha rwakaderera uye kuderera kwakaderera kana uchimhanya nekumhanya kukuru.Iyo chaiyo inorukwa inotonhorera mukati uye ine mhango, uye ine 45 ° ina-petal claw broach mechanism.Kumashure kumagumo kweiyo chaiyo spindle ine hydraulic punching cylinder kuitira nyore kutsiva chishandiso.

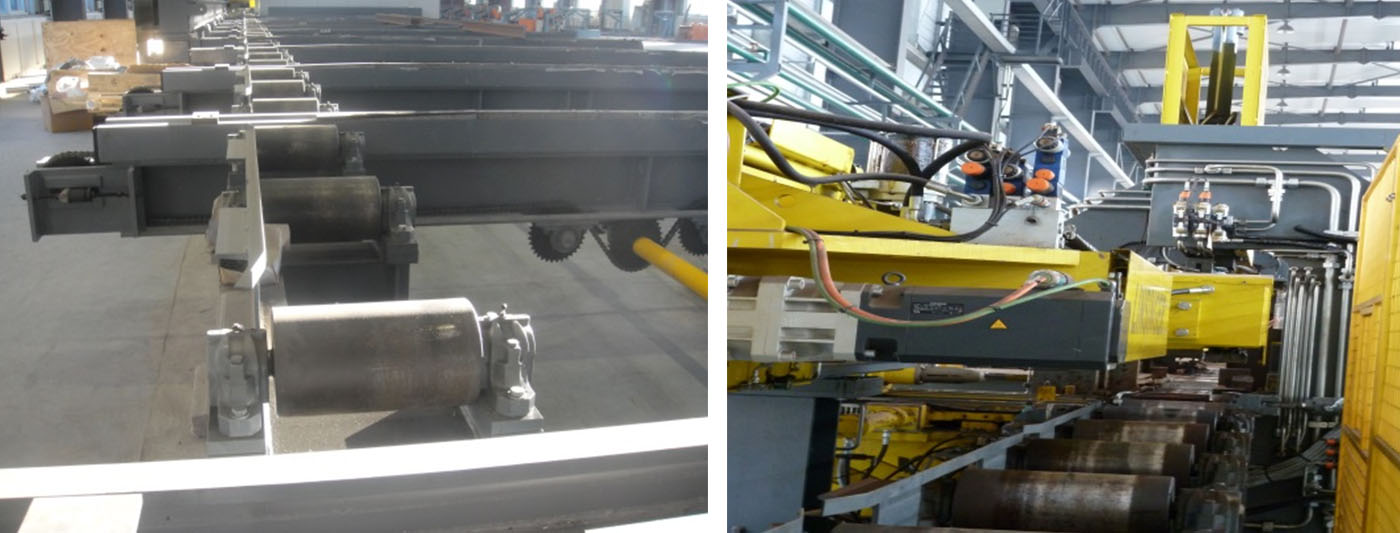

5. Workbench

Workbench inotora simbi yesimbi welding chimiro, pre-kurapwa kunoitwa kusati kwatungidzwa, uye mushure mekuputira, kuzorora kwekushushikana uye kupisa kwekuchembera kurapwa kunoitwa kuti ive nechokwadi uye kugadzikana.

6. Chip kubvisa hurongwa

Iyo otomatiki chip conveyor ndeye flat cheni mhando, ine huwandu hweseti maviri.Imwe seti inoshandiswa kune yekucheka unit uye inoiswa pasi pedivi resaha blade.Imwe seti inoshandiswa kune yekuchera unit, iyo inoiswa pakati pemubhedha uye workbench.Iwo mafirita esimbi anowira pane chip conveyor kuburikidza neiyo chip gidhi pane yebasa bhenji, uye mafirita esimbi anotakurwa kubhokisi resimbi rekuisa kumusoro kuburikidza nechip conveyor.

7. Lubrication system

Kune maviri seti epakati otomatiki lubrication masisitimu, imwe yeiyo sawing unit uye imwe yekuchera unit.Iyo otomatiki lubrication sisitimu inoita kupindirana kwekuzora pane iyo linear rolling guide pair, bhora screw pair, uye rack uye pinion pair kuti ive nechokwadi chavo uye hupenyu hwesevhisi.

8. Electrical system

Iyo yemagetsi sisitimu inotora Nokia 828D nhamba yekudzora sisitimu, inokwana seti mbiri, imwe seti inoshandiswa kudzora sawing unit, yakatwasuka yekudyisa rack, yekudyisa roller tafura uye yepakati roller tafura.Imwe seti inoshandiswa kudzora iyo yekuchera unit, bhenji rekushanda 1, yakatwasuka yekurodha rack uye bhenji rebasa.

| AIHWA. | Item | Brand | Origin |

| 1 | Linear guide pair | HIWIN | Taiwan, China |

| 2 | CNC system 828D | Siemens | Jerimani |

| 3 | Servo motor | Siemens | Jerimani |

| 4 | Coding system | LDMinkjet printer | Shanghai, China |

| 5 | Hydraulic mafuta pombi | Justmark | Taiwan, China |

| 6 | Drag cheni | CPS | Chammhembe Koria |

| 7 | Magiya, machira | APEX | Taiwan, China |

| 8 | Precision reducer | APEX | Taiwan, China |

| 9 | Precision spindle | KENTURN | Taiwan, China |

| 10 | Zvikamu zvikuru zvemagetsi | Schneider | Furanzi |

Ongorora: Zviri pamusoro ndiye mupi wedu wakajairika.Zvinogona kutsiviwa nemhando dzakafanana dzeimwe mhando kana mutengesi ari pamusoro apa asingakwanise kugovera zvinhu kana paine chinhu chakakosha.

Kambani Muchidimbu Profile  Factory Information

Factory Information  Gore negore Kukwanisa Kugadzira

Gore negore Kukwanisa Kugadzira  Trade Ability

Trade Ability