Mutsetse Wekugadzira Wakasanganiswa weRDS13 CNC Rail Saw and Drill

| Chinhu | paramita | Tsanangudzo |

| Muenzaniso wechitima chepakutanga | Rudzi rwezvinhu | 50Kg/m,60 Kg/m,75 kg/m kuomarara 340~400HB |

| Chiteshi chesimbi che alloy, chiteshi chesimbi che alloy, kuomarara 38 HRC~45 HRC | ||

| Saizi yechitima | Kureba kwezvinhu zvisina kubikwa | 2000~1250mm |

| Zvinodiwa pakugadzirisa | Zvinhukureba | 1300~800mm |

| Zvinhukushivirira kureba | ± 1mm | |

| Kuguma kwechiso chakamira zvakanaka | <0.5mm | |

| Dhayamita yekuchera | φ31~φ60mm | |

| Dhayamita yegombakushivirira | 0~0.5mm | |

| Kureba kwegomba | 60~100mm | |

| Main technical parameters emuchina | Nzira yekucheka | Saha rakatenderera (rinomhanya zvakanyanya) |

| Simba remota yekurukisa | 37kW | |

| Dhayamita yebanga rekucheka | Φ660mm | |

| Kumhanya kwakanyanya kweX axis | 25m/miniti | |

| Kumhanya kwakanyanya kweZ axis | 6m/miniti | |

| Mhando yedhirowa yedhirowa | BT50 | |

| KubooraKumhanya kwechirukiso | 3000r/min | |

| KubooraSimba remota yeservo yesimbi | 37kW | |

| Kumhanya kwakanyanya kweX, Y, Z axis | 12m/miniti | |

| Chamfering spindle mhando | NT40 | |

| Chinotenderera chinotenderera RPM Max. | 1000 | |

| Simba remota yeChamfering spindle | 2.2 kW | |

| Kumhanya kwekufamba kweY2 axis neZ2 axis | 10m/miniti | |

| Chigadziko chemagetsi chisingaperi chemagnetic | 250×200×140mm(mumwe200×200×140mm) | |

| Kusvuta basa | ≥250N/cm² | |

| Sisitimu yekubvisa machipisi | 2seti | |

| Rudzi rwechip conveyor | Cheni yakati sandara | |

| Kukurumidza kubvisa chips | 2m/miniti | |

| Sisitimu yeCNC | Siemens828D | |

| Huwandu hwemasisitimu eCNC | 2seti | |

| Huwandu hwemasanhu eCNC | 6+1 axis,2+1 axis | |

| Kureba kwetafura yebasa | 700mm | |

| Kureba kwetafura yebasa | anenge 37.8m×8m×3.4m |

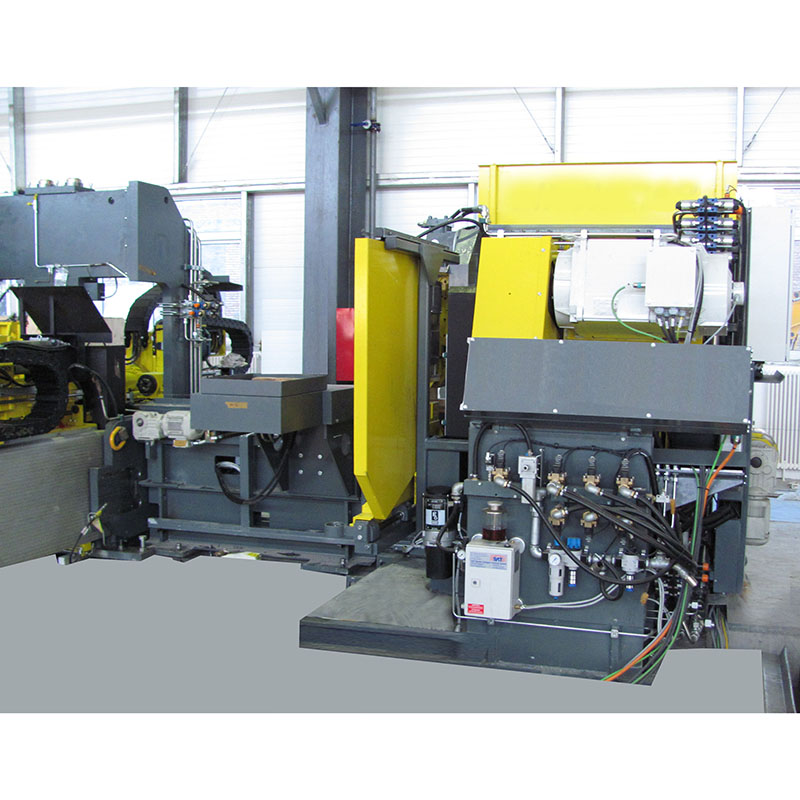

1. Pane mudziyo wekubvisa machipisi ebanga resaw blade pachikamu chekucheka, uyo une basa rekubvisa madota ehuswa kubva pabanga rekucheka. Mudziyo wekutonhodza nekuisa mafuta unonyorovesa nekutonhodza nzvimbo yekucheka, izvo zvinovandudza hupenyu hwebasa rebanga rekucheka. gwara rekutungamira, uye koramu inofambiswa inoiswa pamuchina.

2. Sisitimu yekunyora makodhi

Sisitimu yekunyora makodhi yakaiswa padivi rekunze re power head ram, uye ine komputa inochengetedza mapurogiramu ekuronga nekudzora sisitimu yekunyora makodhi.

3. Chigadziko chekuboorera

Chimiro chembiru chinoshandiswa, uye mbiru yacho inoshandisa chimiro chakasungirirwa nesimbi. Mushure mekugadziriswa kwesimbi uye kuchembera kwekugadzira, kugadzikana kwekugadzirisa kunosimbiswa.

4. Chishongo chemusoro chekuchera

Chigadziko chekuboorera chakagadzirwa se "ram" chine simba rakasimba. Bhandi re "timing" rine simba rekudhonza, rinogara kwenguva refu, ruzha rwakaderera uye kudedera kwakaderera kana richimhanya nekumhanya kukuru. Chigadziko chekunyatsopinza chinotonhorera mukati uye chine gomba, uye chine nzira ye 45° four-petal claw broach. Kumashure kwechigadziko chekunyatsopinza kwakagadzirwa nesilinda yekupunha ye hydraulic kuti zvive nyore kutsiva zvishandiso.

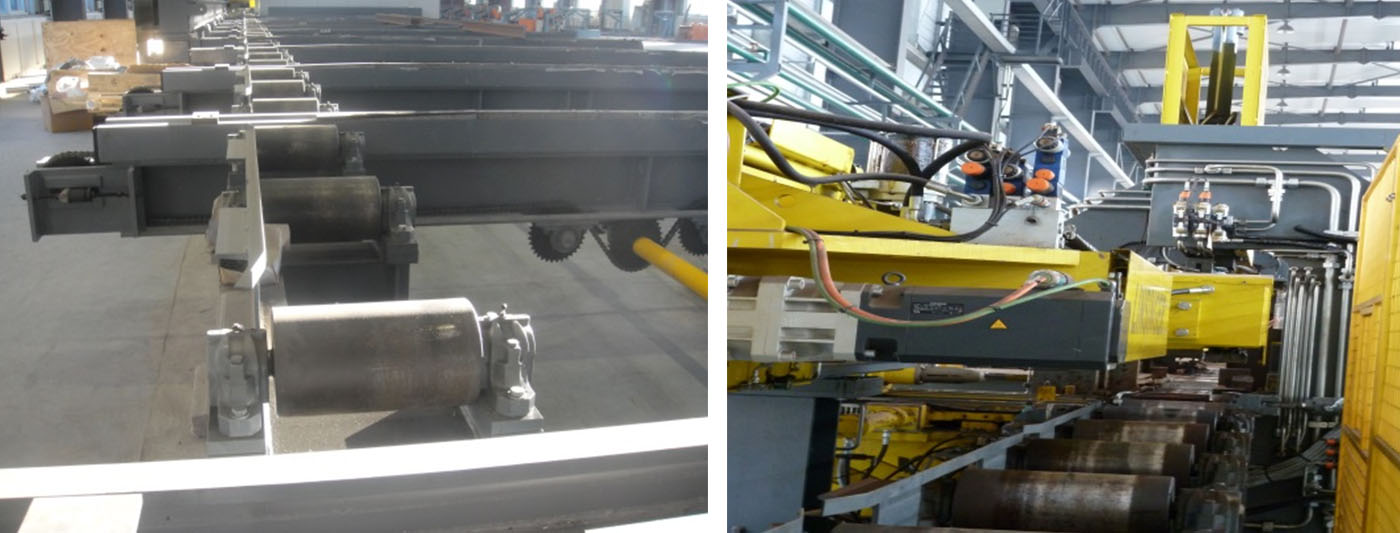

5. Bhenji rebasa

Bhenji rebasa rinoshandisa dhizaini yekuwedera simbi, kurapwa kunoitwa usati wawedera, uye mushure mekuwedera, kuderedzwa kwekushushikana uye kurapwa kwekukwegura kwekupisa kunoitwa kuti ive nechokwadi chekuti zvakarurama uye zvakagadzikana.

6. Sisitimu yekubvisa machipisi

Chip conveyor otomatiki imhando yecheni yakatsetseka, ine maseti maviri ese. Seti imwe inoshandiswa pakucheka uye inoiswa pasi pedivi rebanga rekucheka. Imwe seti inoshandiswa pakucheka, iyo inoiswa pakati pemubhedha nebhenji rekushandira. Mafaira esimbi anowira pachip conveyor kuburikidza negwara rechip riri pabhenji rekushandira, uye mafaira esimbi anotakurwa kuenda kubhokisi rekuisa simbi riri pamusoro kuburikidza nechip conveyor.

7. Sisitimu yekuzora mafuta

Kune maseti maviri ehurongwa hwekuzora otomatiki, rimwe rekugadzira simbi uye rimwe rekugadzira simbi. Hunhu hwekuzora otomatiki hunoita kuti simbi ikwanise kuzora nguva nenguva pamhando ye "linear rolling guide pair", "ball screw pair", uye "rack and pinion pair" kuti ive nechokwadi chekuti dzakarurama uye dzinogara kwenguva refu.

8. Sisitimu yemagetsi

Sisitimu yemagetsi inoshandisa sisitimu yekudzora nhamba yeSiemens 828D, ine maseti maviri, seti imwe inoshandiswa kudzora unit yekucheka, rack yekudyisa yakatambanudzwa, tafura yekudyisa inotenderera uye tafura yepakati inotenderera. Imwe seti inoshandiswa kudzora unit yekuboorera, workbench 1, rack yekurodha yakatambanudzwa uye workbench.

| AIHWA. | Chinhu | Rudzi | Kwakatangira |

| 1 | Peya yekutungamira yakatsetseka | HIWIN | Taiwan, China |

| 2 | Sisitimu yeCNC 828D | Siemens | Jerimani |

| 3 | Smota ye ervo | Siemens | Jerimani |

| 4 | Sisitimu yekunyora makodhi | Purinda yeLDMinkjet | Shanghai, China |

| 5 | Pombi yemafuta ehydraulic | Justmark | Taiwan, China |

| 6 | Cheni yekudhonza | CPS | Chammhembe Koria |

| 7 | Magiya, ma racks | APEX | Taiwan, China |

| 8 | Chinoderedza manyorerwo | APEX | Taiwan, China |

| 9 | Chokurukisa nemazvo | KENTURN | Taiwan, China |

| 10 | Zvikamu zvikuru zvemagetsi | Schneider | Furanzi |

Cherechedza: Zviri pamusoro apa ndizvo zvatinotengesa. Zvinogona kutsiviwa nezvinhu zvemhando imwe chete kana mutengesi ari pamusoro apa asingakwanise kupa zvinhu zvacho kana paine chimwe chinhu chakakosha.

Nhoroondo Pfupi yeKambani  Ruzivo rweFekitori

Ruzivo rweFekitori  Kugona Kwekugadzira Kwegore Negore

Kugona Kwekugadzira Kwegore Negore  Kugona Kwekutengeserana

Kugona Kwekutengeserana