Muchina wekudhonza wePLM Series CNC Gantry mobile

| Item | Name | paramita | |||

| PLM3030-2 | PLM4040-2 | PLM5050A-2 | PLM6060-2 | ||

| Kugadzira michina kwakanyanyazvinhusaizi | Kureba x upamhi | 3000*3000 mm | 4000×4000 mm | 5000×5000 mm | 5000×5000 mm |

| Ukobvu hweplate hwakanyanya kucheneswa | 250 mm, Kureba kwayo kunogona kusvika 380mm | ||||

| Basatafura | Saizi yebhenji rebasa | 3500×3000 mm | 4500×4000 mm | 5500×4000 mm | 5500×4000 mm |

| Upamhi hweT-groove | 28 mm | ||||

| Linobereka matanda | 3tmaon/㎡ | ||||

| KubooraChokurukisa | Zvakanakisakubooradhayamita yegomba | φ60 mm | |||

| Chiyero chikuruKureba kweChishandiso vs. Dhayamita yeHole | ≤10()Koronakabhidhichibooreso) | ||||

| ChokurukisaRPM | 30-3000 r/min | ||||

| Chinovhara jira rekurukira | BT50 | ||||

| Simba remota yekurukisa | 2×22kW | ||||

| torque yepamusoro yespindlen≤750r/min | 280Nm | ||||

| Kureba kubva kumucheto wepasi wesimendepatafura yebasa | 280—780 mm ()Gadzirisa zvinoenderana nezvinhuukobvu) | ||||

| Kufamba kwenguva refu kwemutsipa (x-axis) | Kurohwa kwakanyanya | 3000 mm | 4000 mm | 5000 mm | |

| Kumhanya kwekufamba kweX-axis | 0—8m/miniti | ||||

| Simba remota yeservo yeX-axis | 2×2.7kW | ||||

| Pkunyatsorongeka kwekutarisa | X-axis、Y-axis | 0.06mm/ yosesitiroko | 0.08mm/ yosesitiroko | 0.10mm/ yosesitiroko | |

| Kudzokorora kurongeka kwenzvimbo | X-axis、Y-axis | 0.035mm/ yosesitiroko | 0.04mm/ yosesitiroko | 0.05mm/ yosesitiroko | |

| Sisitimu yeHydraulic | Kumanikidzwa / kuyerera kwepombi ye hydraulic | 15MPa /25L/min | |||

| Simba remota yepombi yehydraulic | 3.0 kW | ||||

| Sisitimu yepneumatic | Kumanikidzwa kwemhepo | 0.5 Mpa | |||

| Kubvisa chips nekutonhodza | Rudzi rwechip conveyor | Cheni yakati sandara | |||

| Nhamba yechinhu chinotakura chip | 2 | ||||

| Kukurumidza kubvisa chips | 1m/miniti | ||||

| Chip conveyor motor simba | 2×0.75kW | ||||

| Kutonhodza maitiro | Kutonhodza kwemukati + kutonhodza kwekunze | ||||

| Kumanikidzwa kukuru | 2MPa | ||||

| Kuyerera kwakanyanya | 2×50L/min | ||||

| Sisitimu yemagetsi | CNC | Siemens 828D | |||

| CNCakisiNhamba | 6 | ||||

| Simba rese remota | Inenge 75kW | ||||

| Zviyero zvese zvemuchina wekushandisa | Kureba × Yakafara × Yakakwirira | Nezvedu 8m×8m×3m | Nezvedu9m×9m×3m | Nezvedu10m×10m×3m | Nezvedu10m×10m×3m |

| Kurema kwese kwemuchina wekushandisa | Inenge 32t | Nezvedu40t | Nezvedu48t | ||

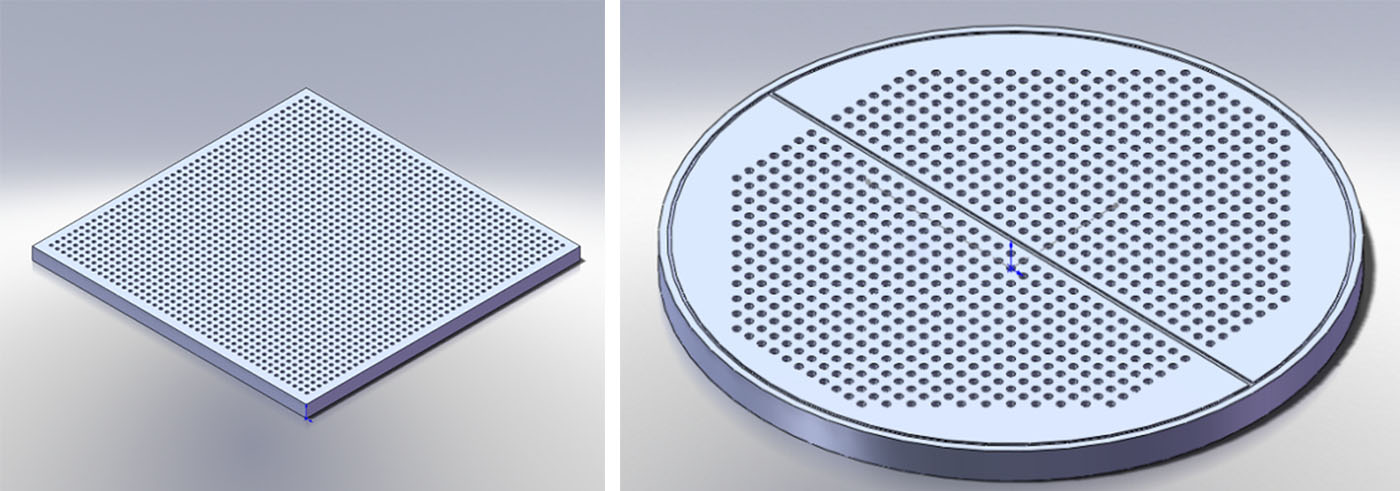

1. Muchina uyu unonyanya kuumbwa nemubhedha nembiru, danda netafura inotsvedza yakatwasuka, bhokisi remagetsi rekuboorera remhando yeram, tafura yebasa, chip conveyor, hydraulic system, pneumatic system, cooling system, centralized lubrication system, electrical system, nezvimwewo.

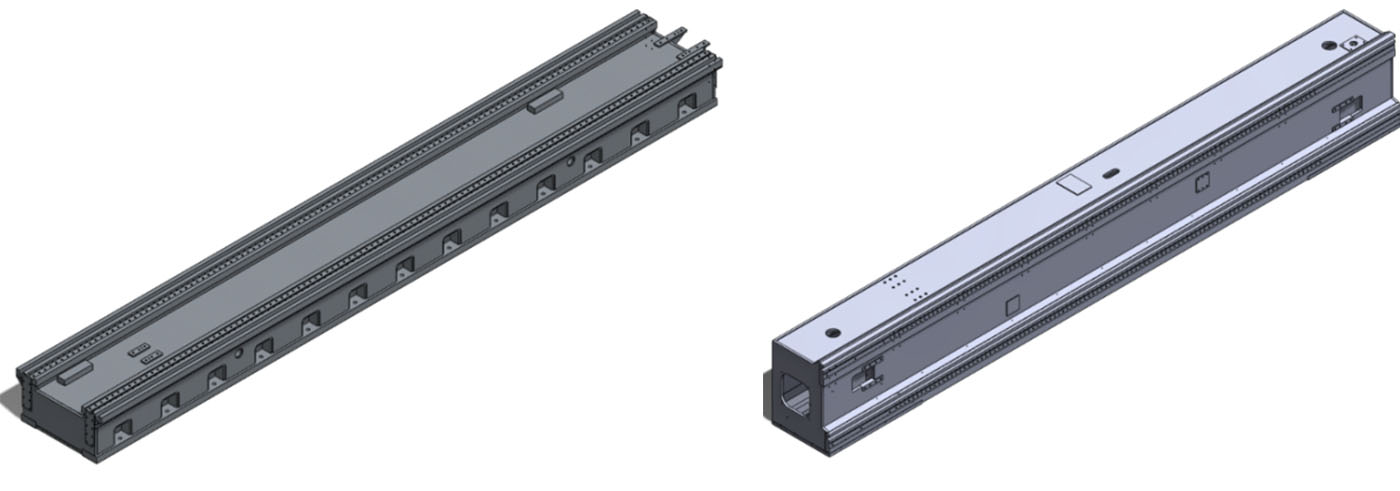

2. Hwaro hwebheya rine kuomarara kwakanyanya, beya rinoshandisa screw chaiyo yakanyatsogadzirwa. Nzvimbo yekuisa yakareba kwenguva refu inoita kuti axis rigidity irambe yakasimba. Beya rinosimbiswa kare nelock nut, uye lead screw inosimbiswa kare. Huwandu hwekutambanudza hunotsanangurwa zvichienderana nekushanduka kwekushisa uye kureba kwelead screw kuti ive nechokwadi chekuti positioning accuracy yelead screw haichinje mushure mekunge tembiricha yakwira.

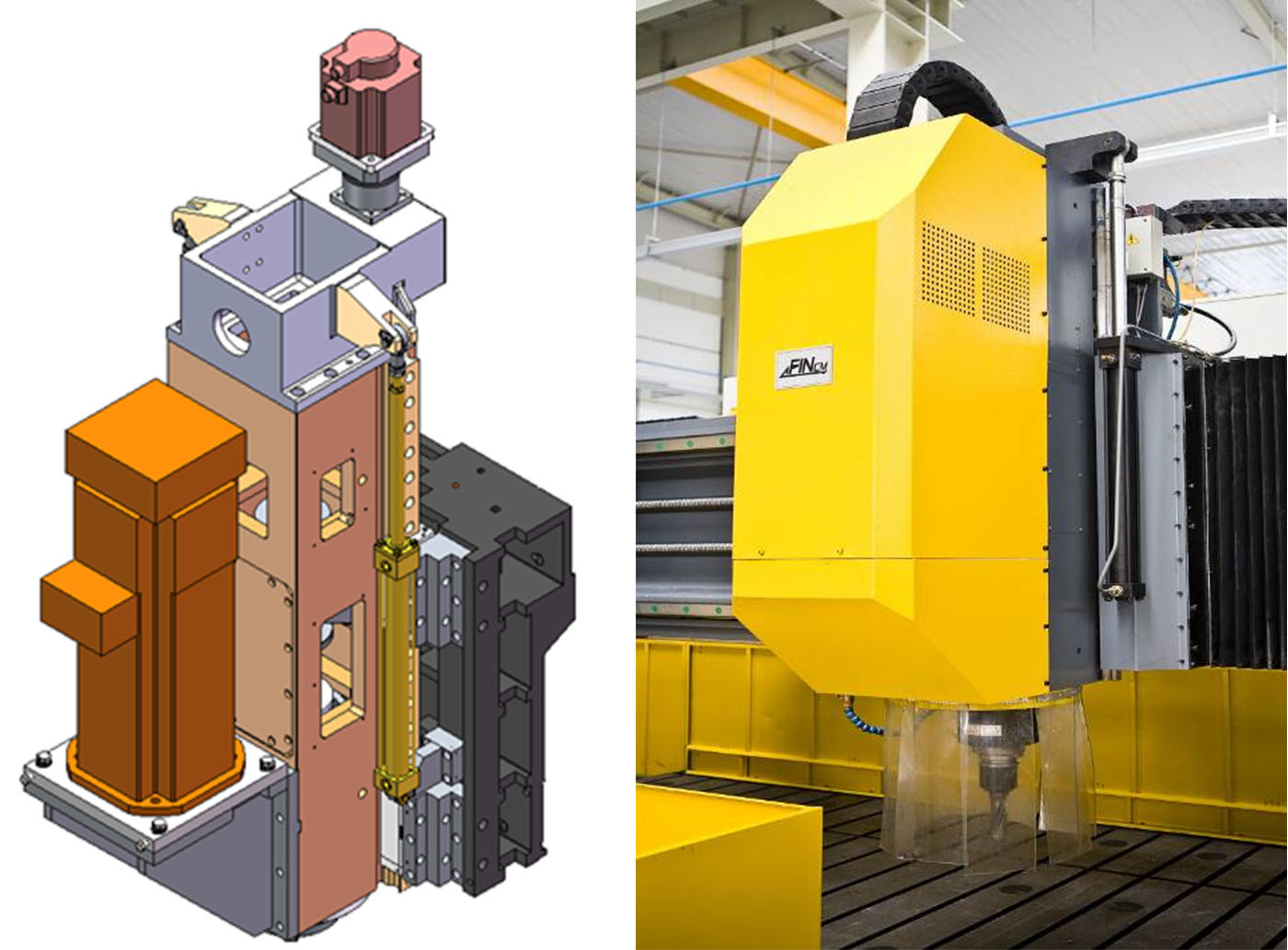

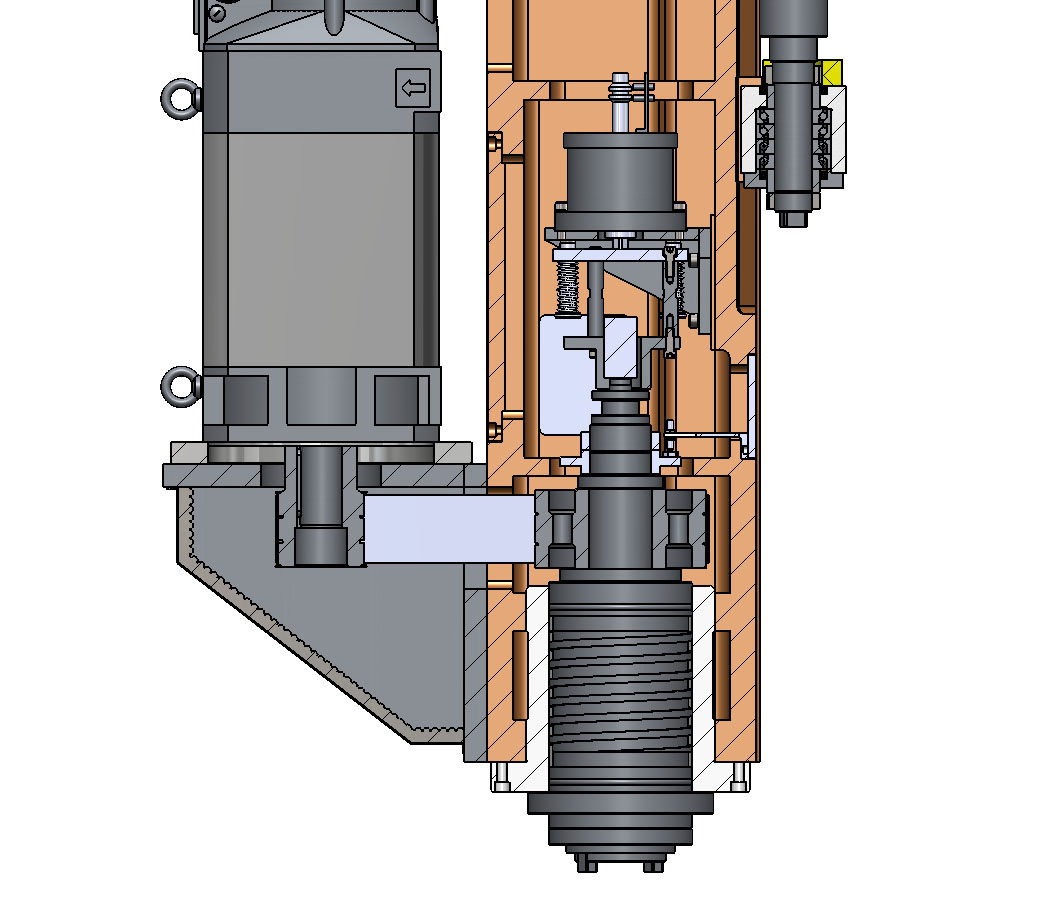

Musoro wesimba rekuchera nekugaya

3. Kufamba kwemusoro wesimba kwakamira (Z-axis) kunotungamirirwa nematanho maviri ekutungamira akarongwa param, ane gwara rakanaka, resistance yakanyanya uye friction coefficient yakaderera. Bhora rinotyaira rinofambiswa nemota yeservo kuburikidza neplanetary reducer chaiyo, ine simba guru rekudyisa.

4. Muchina uyu unoshandisa machipisi maviri akatsetseka ari pamativi ese etafura yebasa. Machipisi esimbi nechinhu chinotonhodza zvinounganidzwa muchinhu chinotonhodza, uye machipisi esimbi anotakurwa kuenda kuchinhu chinotonhodza, izvo zviri nyore kubvisa machipisi; chinhu chinotonhodza chinodzokororwazve.

5. Muchina uyu unopa nzira mbiri dzekutonhodza—kutonhodza kwemukati nekutonhodza kwekunze, izvo zvinopa mafuta akakwana uye kutonhodza kune chishandiso uyezvinhupanguva yekucheka machipisi, izvo zvinovimbisa zviri nanichibooresomhando yekushanda. Bhokisi rekutonhodza rine zvinhu zvinoona mwero wemvura uye zvinopa alarm, uye kumanikidzwa kwekutonhodza kwakajairika i2MPa.

Chokurukisa nemazvo

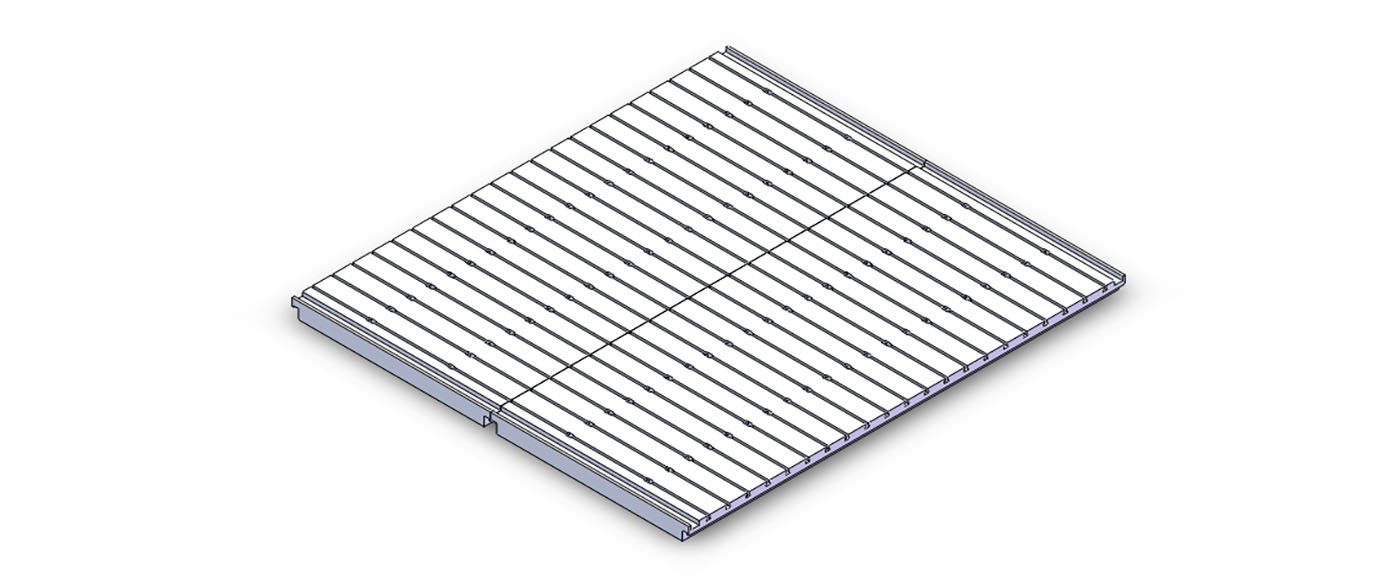

6. Machira ekufambisa eX-axis kumativi ese emuchina ane machira ekudzivirira esimbi isina ngura, uye machira ekufambisa eY-axis ane machira ekudzivirira anochinjika kumativi ese.

Chip conveyor

Mudziyo wekutonhodza

Chishandiso chekuzora otomatiki

7. Muchina uyu unewo chinhu chinoona mativi ekunze che photoelectric kuti chiite kuti denderedzwa rionekwe zvakanaka.

Sisitimu yeSiemens CNC

| AIHWA. | Zita | Rudzi | Nyika |

| 1 | Njanji yekutungamira yakatsetseka | HIWIN kana PMI | Taiwan, China |

| 2 | Sisitimu Yekudzora CNC | Siemens | Jerimani |

| 3 | Servo motor nemutyairi | Siemens | Jerimani |

| 4 | Chokurukisa nemazvo | KENTURN kana SPINTECH | Taiwan, China |

| 5 | Vharuvhu yehydraulic | YUKEN KANA Justmark | Japani |

| 6 | Pombi yemafuta | Justmark | Taiwan, China |

| 7 | Sisitimu yekuisa mafuta otomatiki | BIJUR KANA HERG | USA kana Japan |

| 8 | Mabhatani, marambi ekuratidza zviratidzo nezvimwe zvinhu zvikuru zvemagetsi | SCHBEIDER/ABB | France/Germany |

Cherechedza: Zviri pamusoro apa ndizvo zvatinotengesa. Zvinogona kutsiviwa nezvinhu zvemhando imwe chete kana mutengesi ari pamusoro apa asingakwanise kupa zvinhu zvacho kana paine chimwe chinhu chakakosha.

Nhoroondo Pfupi yeKambani  Ruzivo rweFekitori

Ruzivo rweFekitori  Kugona Kwekugadzira Kwegore Negore

Kugona Kwekugadzira Kwegore Negore  Kugona Kwekutengeserana

Kugona Kwekutengeserana