PHD2020C CNC Drilling Machine yeSimbi Plates

| Kugadzira michina kwakanyanyazvinhusaizi | Dhayamita | φ2000mm |

| Ndiro | 2000 x 2000mm | |

| Ukobvu hweplate hwakanyanya kucheneswa | 100 mm | |

| bhenji rebasa | Upamhi hweT-groove | 22 mm |

| Musoro wesimba rekuchera | Kureba kwedhayamita yekuchera kwesimbi inomhanyisa kutenderedza simbi | φ50 mm |

| Dhayamita yepamusoro yekuboorwa kwecarbide drill yakagadzirwa nesimende | φ40 mm | |

| Dhayamita yepamusoro yekucheka mill | φ20mm | |

| Chinovhara jira rekurukira | BT50 | |

| Simba guru remota | 22kW | |

| Kupisa kukuru kwesimbi torquen≤750r/min | 280Nm | |

| Kureba kubva kumucheto wepasi wesimendepatafura yebasa | 250—600 mm | |

| Kufamba kwenguva refu kwemutsipa (x-axis) | ZvakanakisaStroke | 2050 mm |

| Kumhanya kwekufamba kweX-axis | 0—8m/miniti | |

| Simba remota yeservo yeX-axis | Inenge 2×1.5kW | |

| Kufamba kwemusoro wesimba padivi(Yakabatana neY) | Kurova kwakanyanya kwemusoro wesimba | 2050mm |

| Simba remotokari yeservo yeY-axis | Inenge 1.5kW | |

| Kufamba kwesimba remusoro wesimba(Z akisi) | Kufamba kweZ-axis | 350 mm |

| Simba remotokari yeZ-axis servo | Inenge 1.5 kW | |

| kunyatsorongeka kwenzvimbo | X-axis,Y-axis | 0.05mm |

| Kudzokorora kurongeka kwenzvimbo | X-axis,Y-axis | 0.025mm |

| Sisitimu yepneumatic | Kumanikidzwa kwemhepo kunodiwa | ≥0.8MPa |

| Chip conveyor motor simba | 0. 45kW | |

| Kutonhodza | Modhi yekutonhodza yemukati | kutonhora kwemhepo-mhute |

| Nzira yekutonhodza yekunze | Kutonhodza kwemvura inotenderera | |

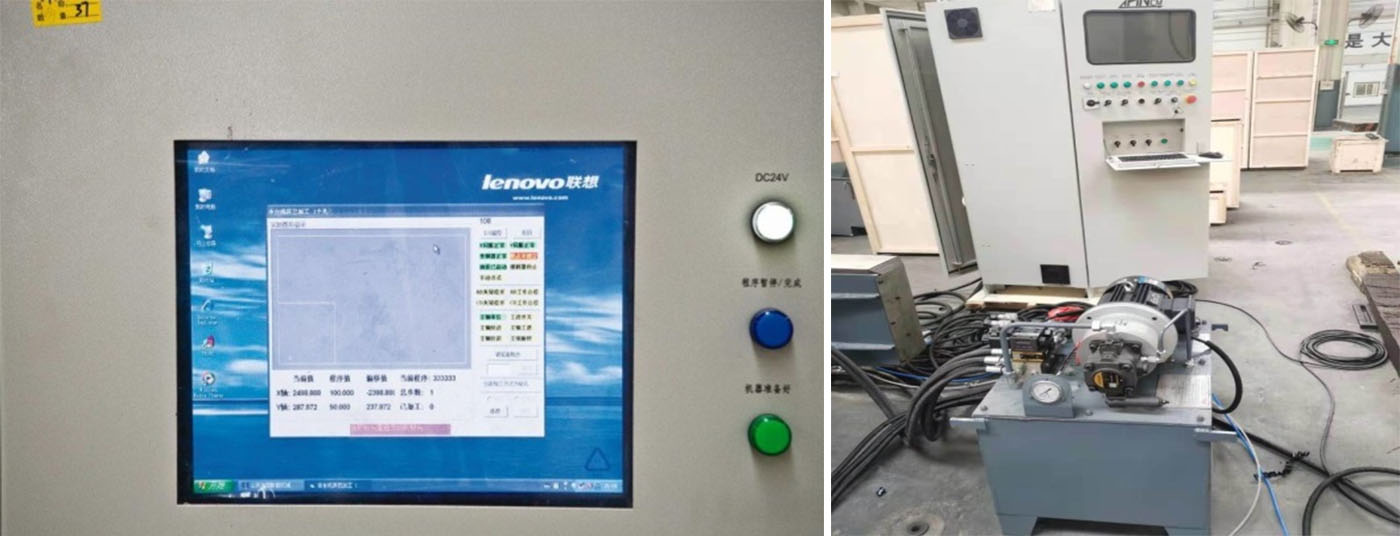

| Sisitimu yemagetsi | CNC | Siemens 808D |

| Huwandu hwemasanhu eCNC | 4 | |

| Muchina Mukuru | Huremu | Kurema kunenge 8500kg |

| Chiyero chose(L× W × H) | Inenge 5300()3300)×3130×2830 mm |

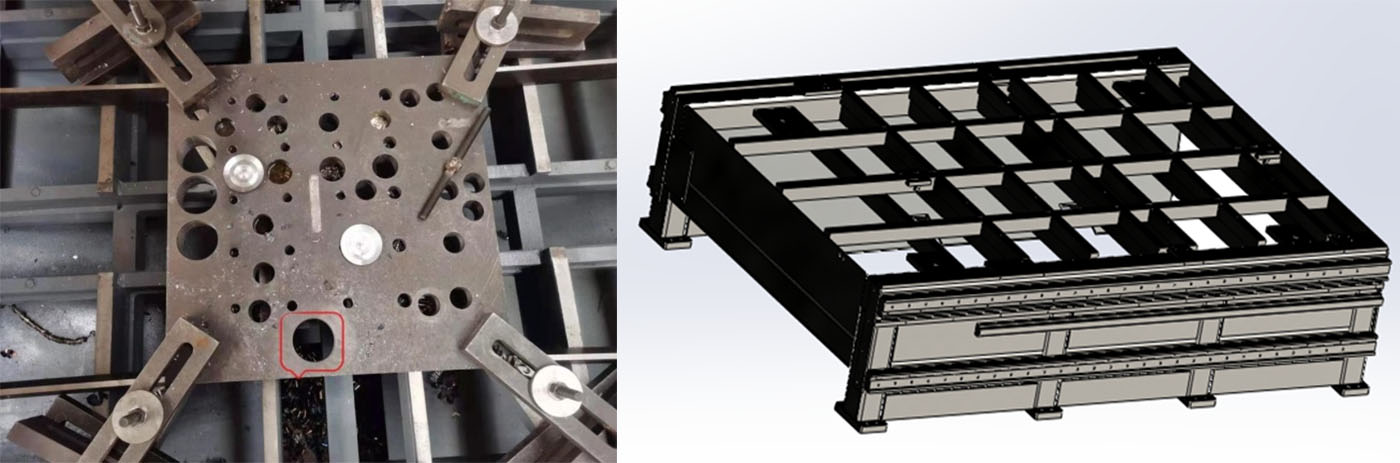

1. Muchina uyu une mubhedha ne longitudinal slide plate, gantry ne transverse slide table, drilling power head, chip removal device, pneumatic system, spray cooling system, centralized lubrication system, electrical system nezvimwewo.

2. Spindle yemusoro wesimba rekuboorera inoshandisa spindle chaiyo yakagadzirwa muTaiwan, ine kutenderera kwakanyanya uye kuomarara kwakanaka. Yakashongedzerwa negomba reBT50 taper, zviri nyore kuchinja maturusi. Inogona kubatanidza twist drill ne cemented carbide drill, ine mashandisirwo akasiyana-siyana. Zvigayo zvidiki zvemadhayamita zvinogona kushandiswa pakugaya zvishoma. Spindle inofambiswa nemota ine mafrequency akasiyana-siyana, ine mashandisirwo akasiyana-siyana.

3. Chishandiso chemuchina chine maaxes mana eCNC: gantry positioning axis (x-axis, double drive); Transverse positioning axis (Y axis) ye drilling power head; Drilling power head feed axis (Z axis). CNC axis yega yega inotungamirirwa ne precision linear rolling guide rail uye inofambiswa neAC servo motor + ball screw.

4. Chishandiso chemuchina chine chinotakura chip chakatsetseka pakati pemubhedha wemuchina. Machipisi esimbi anounganidzwa muchina wekutakura chip, uye machipisi esimbi anotakurwa kuenda kuchina wekutakura chip, izvo zviri nyore kubvisa machipisi; Chinotonhodza chinodzokororwa.

5. Zvivharo zvinochinjika zvinodzivirira zvinoiswa pazvigadziko zve x-axis ne y-axis zvinotungamira kumativi ese echishandiso chemuchina.

6. Sisitimu yekutonhodza ine mhedzisiro yekutonhodza kwemukati nekutonhodza kwekunze.

7. Sisitimu yeCNC yemuchina wekushandisa ine Siemens 808D uye vhiri remagetsi, rine basa rakasimba uye riri nyore kushandisa. Ine RS232 interface uye ine mabasa ekugadzirisa preview uye review. Iyo operation interface ine mabasa e man-machine dialogue, error compensation uye automatic alarm, uye inogona kuita automatic programming yeCAD-CAM.

| AIHWA. | Zita | Rudzi | Nyika |

| 1 | Lnjanji yekutungamira inear | HIWIN/PMI/ABBA | Taiwan, China |

| 2 | Peya yebhora | HIWIN/PMI | Taiwan, China |

| 3 | CNC | Siemens | Jerimani |

| 4 | mota yeservo | Siemens | Jerimani |

| 5 | Mutyairi weServo | Siemens | Jerimani |

| 6 | Chokurukisa nemazvo | KENTURN | Taiwan, China |

| 7 | Kuzora mafuta kwepakati | BIJUR/HERG | USA / Japani |

Cherechedza: Zviri pamusoro apa ndizvo zvatinotengesa. Zvinogona kutsiviwa nezvinhu zvemhando imwe chete kana mutengesi ari pamusoro apa asingakwanise kupa zvinhu zvacho kana paine chimwe chinhu chakakosha.

Nhoroondo Pfupi yeKambani  Ruzivo rweFekitori

Ruzivo rweFekitori  Kugona Kwekugadzira Kwegore Negore

Kugona Kwekugadzira Kwegore Negore  Kugona Kwekutengeserana

Kugona Kwekutengeserana